inserting Machines

AUTO AND MANUAL INSERTING MACHINES

PEMSERTER® Series 4® Press

PEMSERTER® Series 4® Press

Operation: Manual

Type: Pneumatic

Force: 12,000 lbs. / 53.4 kN

Throat Depth: 18″ / 45.7 cm

HAEGER® 618 sUPER sPEED

Haeger 618-SS

Operation: Auto/Manual

Type: Hydraulic

Force: 12,000 lbs. / 53.4 kN

Throat Depth: 18″ / 45.7 cm

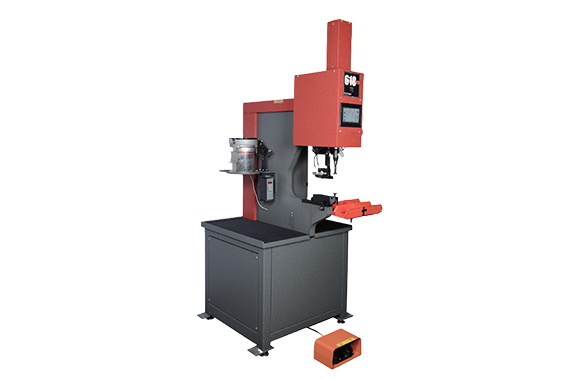

Haeger® 618 Plus

Haeger® 618 Plus

Operation: Auto/Manual

Type: Hydraulic

Force: 12,000 lbs. / 53 kN

Throat Depth: 18 in. / 450 mm

Haeger® 824 Plus

Haeger® 824 Plus

Operation: Auto/Manual

Type: Hydraulic

Force: 16,000 lbs. / 72 kN

Throat Depth: 24 in. / 610 mm

Haeger® 618 MSPe

Haeger® 618 MSPe

Operation: Auto/Manual

Type: Hydraulic

Force: 12,000 lbs. / 53 kN

Throat Depth: 18 in. / 450 mm

Haeger® 824 MSPe

Haeger® 824 MSPe

Operation: Auto/Manual

Type: Hydraulic

Force: 16,000 lbs. / 72 kN

Throat Depth: 24 in. / 610 mm

Haeger® 824 WindowTouch-4e

Haeger® 824 WindowTouch-4e

Operation: Auto/Manual

Type: Hydraulic

Force: 16,000 lbs. / 72 kN

Throat Depth: 24 in. / 610 mm

Haeger® 824 OneTouch-4e Lite

Haeger® 824 OneTouch-4e Lite

Operation: Auto/Manual

Type: Hydraulic

Force: 16,000 lbs. / 72 kN

Throat Depth: 24 in. / 610 mm

Haeger® 824 OneTouch-4e

Haeger® 824 OneTouch-4e

Operation: Fully Automatic

Type: Hydraulic

Force: 16,000 lbs. / 72 kN

Throat Depth: 24 in. / 610 mm

WRITE TO US

For general

We appreciate your feedback, so feel free to contact us about any issues you would like to alert us to, by telephoning (03) 9796 5260 or use the form below to send us an e-mail:

TALK TO US

To receive this offer contact us about any issues you would like to alert us to, by telephoning (03) 9796 5260 or use the form below to send us an e-mail: