Clinching Machines

CLINCHING MACHINES

RIVCLINCH® 4006 P50 PASS

Cost effective, multi-purpose clinching machine

AUTOMATIC APPROACH – With the new PASS system, your hands are completely free to manipulate your parts! MACHINE RELIABILITY – The risk for oil circuit damage and oil leakage are minimized by the new integrated booster and internal oil circuit we developed! MAINTENANCE TIME & COST REDUCTION with the simplification of mechanical interfaces! A NEW DESIGN FOR A MORE COMPACT MACHINE! Always with OPTIMAL SECURITY

RIVCLINCH®(SPOTCLINCH®)0201IP

Ultra-fast, 100% pneumatic tool. When clinching two or more layers of sheet metal, the material is plastically deformed inside a die through a squeezing process between the punch and the anvil. The joint is created as the material flows sideways pushing out the die walls. The result is a high quality joint, without the need for consumables such as screws or rivets, and without disturbing the coating, thus eliminating the need for

RIVCLINCH® 0404 IP

Ultra-fast, 100% pneumatic tool. When clinching two or more layers of sheet metal, the material is plastically deformed inside a die through a squeezing process between the punch and the anvil. The joint is created as the material flows sideways pushing out the die walls. The result is a high quality joint, without the need for consumables such as screws or rivets, and without disturbing the coating, thus eliminating the need for

SC 0604 IP

Multi-purpose, jaw type clincher, ideally suited for applications with medium distance to access the joint.

Wide opening with safe pre-stroke, by automatic fast closing of the work head (patents pending).

- Weight of work head (kg) – 7.0 to 7.3

- Setting force (kN) – 35

- Cycle time – 0.5 – 0.9

- Work stroke (mm) – 7

- Jaws opening (mm) – 36

- Depth of jaw (mm) – 60

- thickness Mild steel (mm) – 3.0

- thickness Stainless st.(mm) – 2.5

RIVCLINCH®(SPOTCLINCH®)0706IP

100% pneumatic, high capacity clinching tool with large opening jaws.

Metal joining without fasteners

When clinching two or more layers of sheetmetal, the material is plastically deformed inside a die through a squeezing process between the punch and the anvil. The joint is created as the material flows sideways pushing out the die walls.

The result is a high quality joint, without the need for consumables such as screws or rivets, and without disturbing the coating, thus eliminating the need for post touch-up work as occurs with welding.

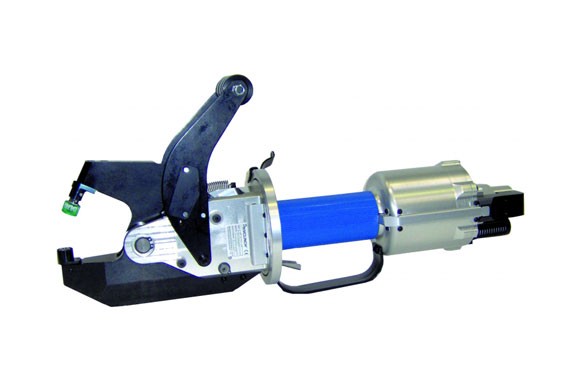

RIVCLINCH®(SPOTCLINCH®)1106P50PASS

Multi-purpose, high capacity portable clinching machine.

Main features

Multi-purpose, high capacity portable clinching machine. One of its unique features is the Passive Approach Stroke System (PASS) which is included. It consists of a separate trigger for the approach stroke, which is run at low force. Once the punch gap is below 8 mm, the second trigger is able to produce the work stroke at high force for the clinching operation. In addition to the safety aspect, the PASS facilitates the positioning of the tool at the clinch joint location prior to trigger the clinching operation. Its design has been optimized for reducing the weight, and for integrating the hydraulic tubing and functions. It is well balanced in all positions by means of a gyroscopic suspension, ball bearing mounted for easy handling.

TAGGER®320

Ultralight stitchfolding machine for sheet material assembly.

Stitchfolding

In stitchfolding, material tabs are cut out by punches. These tabs are then folded back and compressed. The result is a safe joining of sheet material and/or profiles.

WRITE TO US

For general

We appreciate your feedback, so feel free to contact us about any issues you would like to alert us to, by telephoning (03) 9796 5260 or use the form below to send us an e-mail:

TALK TO US

To receive this offer contact us about any issues you would like to alert us to, by telephoning (03) 9796 5260 or use the form below to send us an e-mail: