WELCOME TO CMTS

CMTS operates Australia wide from a fully-owned modern facility in Hallam, Victoria, and is supported by a qualified team of Technical Sales and Service Engineers. Our team is highly competent, factory trained, both within Australia and overseas.

With over 30 years of experience in the metal manufacturing and engineering business, means you receive expert advice and service from consultants who know your business intimately. We have developed a reputation for quality products, excellent service, and professional reliability. We are committed to providing our clients with complete customer satisfaction in a rapidly changing market. Proudly an Australian Owned Family Company.

CMTS are the Australian Distributors for DERATECH Press Brake, Punch Presses, Shears & Fiber Lasers, PEMSERTER & HAEGER Installation Equipment, and PEM Fastener Products. BOLLHOFF Clinching Machines.

HAPPY BIRTHDAY

It’s our 20th Birthday so let’s make it Fabulous for you! CMTS has a Fantastic Offer for you.

NOW IN STOCK AND COMING SOON!

products

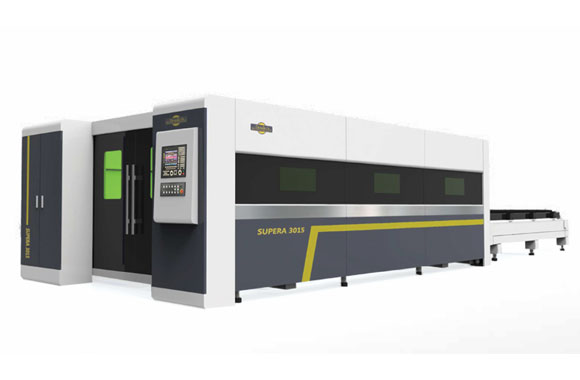

INTRODUCING DERATECH SUPERA-F Fiber Laser

CMTS is proud to announce the are now offering DERATECH SUPERA-F Fiber Laser Cutting Machines

DERATECH SUPERA-F Fiber Laser

It is designed to offer high dynamics during high-speed cutting of thin materials while having all the technology and know-how on board to produce stable and consistent parts in thicker material, where the maximum thickness is only limited by the output power of the laser. The machine can cut the sheets on two different height levels inside the machine, this allows the automatic shuttle table system to change very fast between tables since the tables do not need to make any vertical movement. The fully covered machine assures a perfectly eye-safe operation.

FIBER LASER SOURCE

The Supera can be equipped with MAX or IPG source, from 1 – 12kW

DERATECH & AUTOMATION

OUR SERVICES

Our main focus lies in recognising the individual requirements of our discerning customers so that we can always supply them with a suitable machine with high added value for their sheet metal processing tasks. You can be sure that you will not only save money with our top-quality machines, but also enjoy long-term success when processing sheet metal…

CMTS are the Australian Distributors for DERATECH Press Brake, Punch Presses, Shears & Fiber Lasers. SCHRÖDER Folders and Shears, PEMSERTER & HAEGER Installation Equipment and PEM Fastener Products. BOLLHOFF Clinching Machines.

TESTIMONIALS

“CMTS kept us updated all the way through the process. When the machine was installed, they were fantastic so helpful. They came in and gave my team all the training we needed. They even came back to deliver extra training when we asked. They know that this installation was important to us and treated it with the respect it needed. With CMTS it only took a short time and we were up and running. They are such good people to deal with if more people were like them the world would be a better place.”

“The staff at CMTS did so much work for us on this. They even had to bring in an engineer from Belgium to help with the install. They were outstanding I can’t praise them enough. It took at least a year with everyone working together to get the job done. There were times where the CMTS team were in tears trying to get things done, but they did, and we really appreciate their efforts.”

“We have received the items this morning.

Please accept my gratitude from the bottom of my heart. Excellent service we have received from you guys.”

TALK TO US

To receive this offer contact us about any issues you would like to alert us to, by telephoning (03) 9796 5260 or use the form below to send us an e-mail: